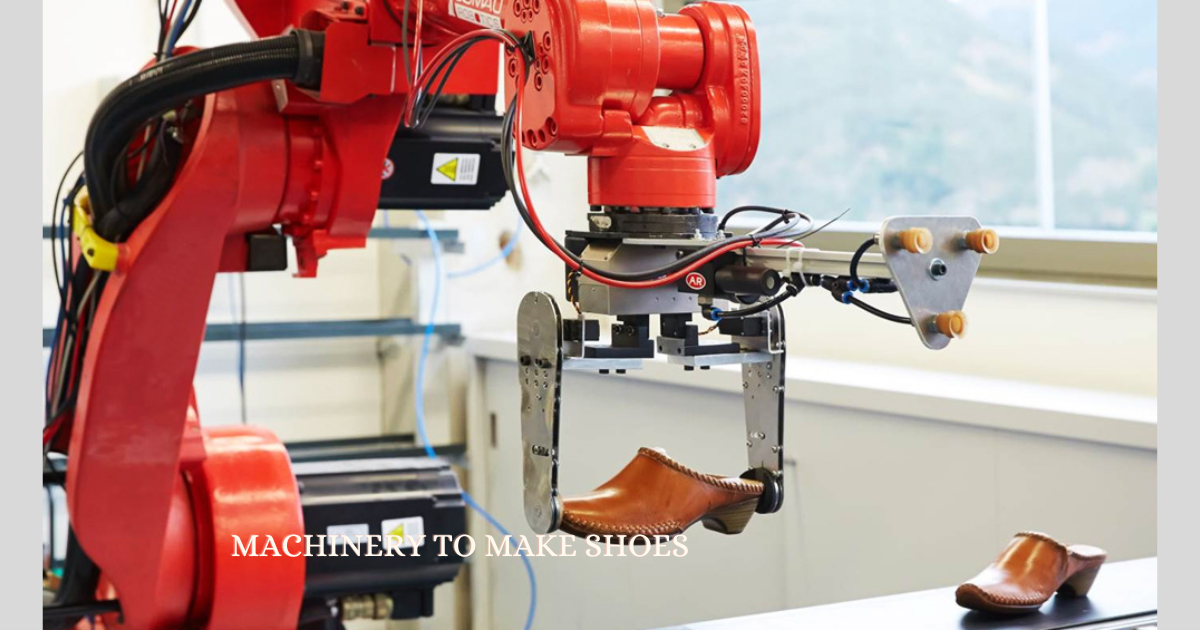

Imagine entering a charming workshop filled with the aroma of freshly cut leather and the steady hammering of a cobbler’s hammer. This image, where each shoe is painstakingly made with care and attention to detail, is reminiscent of a bygone period. But if you travel back to the present, you’ll discover that contemporary shoe factories paint a different picture. Towering machinery hums with activity here, producing pairs of shoes at breakneck speed. This transition from an artisanal trade to a high-tech production line reflects the remarkable advancements in machinery within the shoe industry.

Table of Contents

ToggleChapter 1: A Historical Review of Shoe Manufacturing Equipment

We need to travel back in time to the Industrial Revolution to comprehend machinery development in the shoe industry. In this era, machinery began to have a noticeable impact on shoemaking. The 19th century saw the development of the sewing machine by Elias Howe and Isaac Singer, which transformed production and allowed for the mass manufacture of shoes. As specialized machinery-equipped factories proliferated, shoe production became more efficient and more significant in scope.

Chapter 2: Automation’s Place in the Modern Shoe Industry

Automation is the foundation of the shoe industry in the modern era. The production line is dominated by robotic arms and computer-controlled machinery that perform everything from cutting and sewing to molding and finishing. In addition to increasing productivity, this move towards automation guarantees uniformity and high quality in the finished product.

Chapter 3: Emerging Technologies Changing the Footwear Landscape

Forward-thinking technologies will continue to impact the footwear industry in the future. Of these, 3D printing stands out as revolutionary. Companies such as Adidas and Nike use 3D printing to provide personalized shoes, giving consumers unprecedented customization. The possibilities for shoe design and production are virtually limitless when using 3D printing, from customized uppers to complex midsole patterns.

Chapter 4: Eco-Friendly Methods for Shoe Manufacturing Equipment

As environmental issues gain prominence, shoe manufacturers must prioritize sustainability. Businesses use energy-efficient procedures and recycled materials, adopting eco-friendly practices. The sector wants to address the increasing demand for eco-conscious products while lowering its environmental impact by emphasizing sustainability.

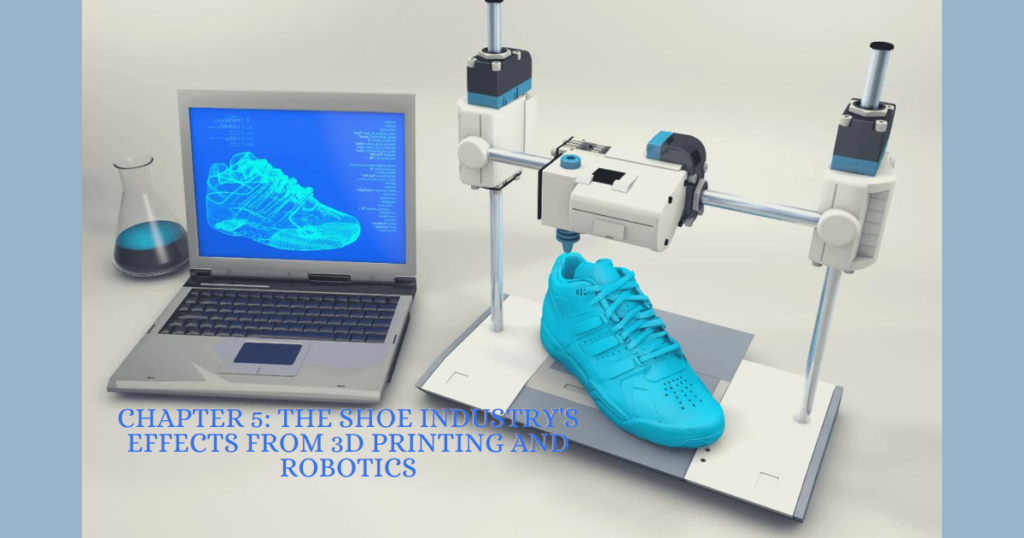

Chapter 5: The Shoe Industry’s Effects from 3D Printing and Robotics

An important turning point in the shoe industry is the combination of robotics and 3D printing. These technologies foster innovation in functionality and design and speed up production. 3D printing expands the possibilities for conventional shoe design by enabling the development of intricate geometries and structures. Robotics, on the other hand, improves precision and efficiency by streamlining industrial processes.

Chapter 6: Progress in the Integration of Materials and Machinery

Alongside technology breakthroughs, materials science is a critical factor in the transformation of the footwear industry. High-performance materials that revolutionize shoe design include graphene and carbon fiber, which offer improved performance and durability. When combined with cutting-edge machinery, these materials provide new possibilities for more robust, lighter, and more resilient footwear.

Chapter 7: Trends in Shoemaking Machinery Customization and Personalization

Due largely to consumer need for distinctive experiences, personalization has become a significant trend in the shoe industry. Customization is welcomed by brands, which let buyers personalize their shoes to fit their tastes. Thanks to cutting-edge manufacturing equipment, customers have never-before-seen control over their footwear’s colors, materials, and fits.

Chapter 8: Prospects and Difficulties for Shoe Manufacturing Equipment

Even with its optimistic outlook, the industry is confronted with various obstacles. Several obstacles to overcome include supply chain interruptions, intellectual property rights, and ethical issues. These difficulties, however, also offer chances for innovation and expansion, propelling the sector towards a future characterized by flexibility and resilience.

Conclusion:

In summary, the fusion of technology and handiwork will define the future of footwear. The shoe business has come a long way from its modest origins to its state-of-the-art developments, thanks to advancements in materials and machinery. One thing is clear as we negotiate the complexity of the current era: footwear’s timeless appeal, where creativity and innovation collide with every step.